About transcended seamer technology

To seam the circumference welding part with a special machine, we can finish making the stable quality and in short time. Also we can provide our products with cost down in cheap price to our customers.

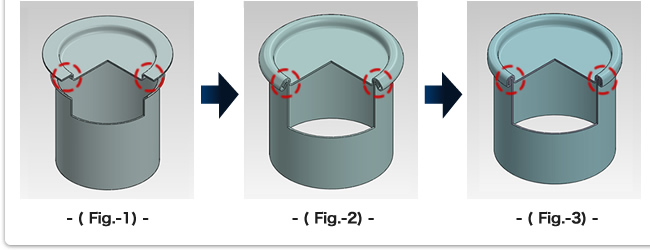

The seamer technology means to occlude can tube and lid can together and keep the airtight inside the can. The representative process can be seen with the following images (Fig.-1 to Fig.-3) and you can see may samples like canned foods and canned water in ordinary life.  |

��START

|

|

Precise machine processing technologyWe correspond to meet our various customers demand by using various pressing equipment and mold machines in our company. We perform the highly precise products for our customers. High level welding processAccording to a different type of vehicle, we design and develop the best layout for our products mixed with good looking and specialized design. |

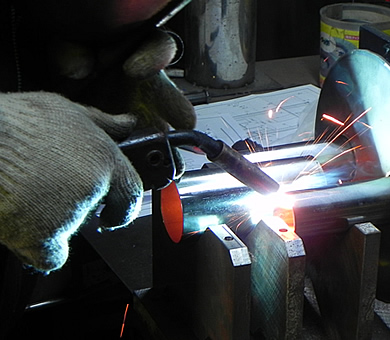

About our bend technology without distortionIn design data, we use the latest 3 dimensional CAD system and draw the data by ourselves to adopt our customer's request by controlled our computer and enable to bend from 38mm to 90mm pipes precisely. So we can manufacture the complex shape products in high quality level. About our bend technology without distortionWe accept any kind of demands from our customers with our various press processing machines and mould machines. Especially our mould machine can be designed and make a mould for our customer's request by our own facility. This makes a total cost for manufacturing the products. Also we process the pipes in precise cut with wire-cut machines and plasma cut machines. Outstanding craftsman groupAll staffs are well skilled masteries so we can realize our products in beautiful finish welding. Sometimes we stop the manufacturing even on progress, and we judge and proceed with the right operation method depending on stand or situation. This makes we can provide the best products for our customers always based on a point of customer's view to us to perform our best efforts to provide our products to our customers. |

|